The truth is, we don’t like to wait. Our society is quickly getting used to having its demands met immediately, especially when it comes to the newest, hottest product on the market.

To meet these demands, manufacturing is evolving to find ways to get products to market faster.

AweSim partners often speak and write about how modeling and simulation/high performance computing help manufacturers get products to market faster during the product development phase. However, modeling and simulation/HPC also is starting to play a role in “Supply Chain Solutions.”

OEMs and the changing face of manufacturing

Third-party logistics companies like Amazon have grown exponentially for their ability to take an order for almost anything and deliver it immediately. Amazon is not making the products (yet), but they are driving the original equipment manufacturers (OEMs) to change how they design and build their products. This demand is creating a new manufacturing paradigm; OEMs are no longer making their entire product. They are relying on an ever-expanding network of suppliers to provide everything from raw material to complete sub-assemblies. The OEM has become an integrator, coordinating a network of suppliers and assembling the parts and sub-assemblies then shipping the product to Amazon or direct to big box outlets like Walmart.

As this network of suppliers expands, and as OEMs try to differentiate themselves from their competitors with things like mass customization (consumers can change and/or add features to create a personalized version of the product), they need to be able to design, assemble and manage a supplier network that can support this new concept.

One answer to this new paradigm is a concept pioneered by the Air Force Research Lab (AFRL): Network Centric Manufacturing (NCM): the rapid assembly and seamless coordination of dynamic supply networks to accelerate production and reduce costs.

NCM focuses on three basic tenets:

- Agile networks that can be easily be reconfigured from order to order with minimal cost and effort.

- Seamless connectivity allowing the networks to share information throughout the network, regardless of systems or technologies.

- Visibility throughout the network permits trading partners to see their product flow through all processes at all suppliers.

The Missing Link

The missing piece to this puzzle is: how do you design and test this new NCM supply chain? One company, Prime Supplier, is developing a module for its Visual Supplier Assessment and Analysis Modules (VSAAMTM) suite of supply chain management tools to address this need.

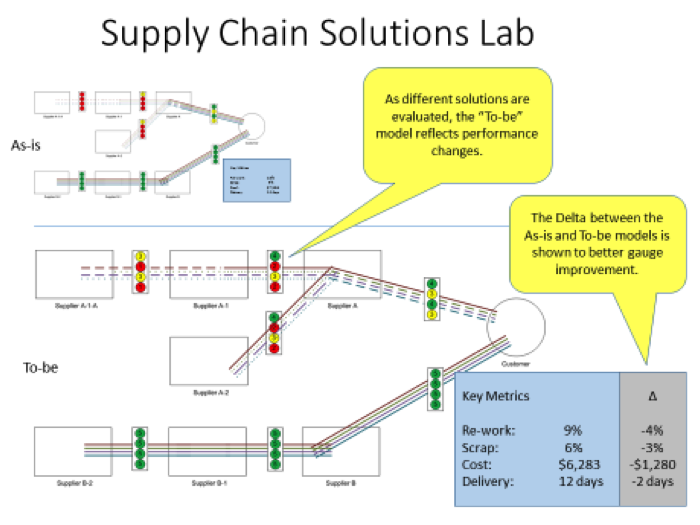

This new module, “Supply Chain Solutions Lab,” will use modeling and simulation/high performance computing to design the supply chain and test multiple “what if” scenarios to assess risk and create mitigation plans to tackle problems before they arise. To ensure all potential risk scenarios are reviewed and analyzed, the model must break down the entire bill of materials and include every step in the manufacturing process from raw material to delivery to the customer. In a complex product this could include hundreds of suppliers and thousands of manufacturing operations/processes.

Some will argue this is too complex and costly, so why bother? Because it only takes one problem to have a significant impact on a company’s bottom line. For example: Remington Firearms lost $40 million in sales one year when a tier-4 supplier had a forming die break and was down for three weeks at the height of the firearms sales season.

So running complete, in-depth analyses becomes very important, and to run these simulations in real time on complex supply chains will require not only a sophisticated model but also supercomputing. That’s where the Ohio Supercomputer Center and AweSim come in. Prime Supplier expects to work with OSC-AweSim to create and beta test this new module this summer.

For more updates on how this proceeds, or if you’re simply interested in learning more about what modeling and simulation/HPC can do for your company, be sure to check out the AweSim website and follow us on Twitter @AweSimApps.